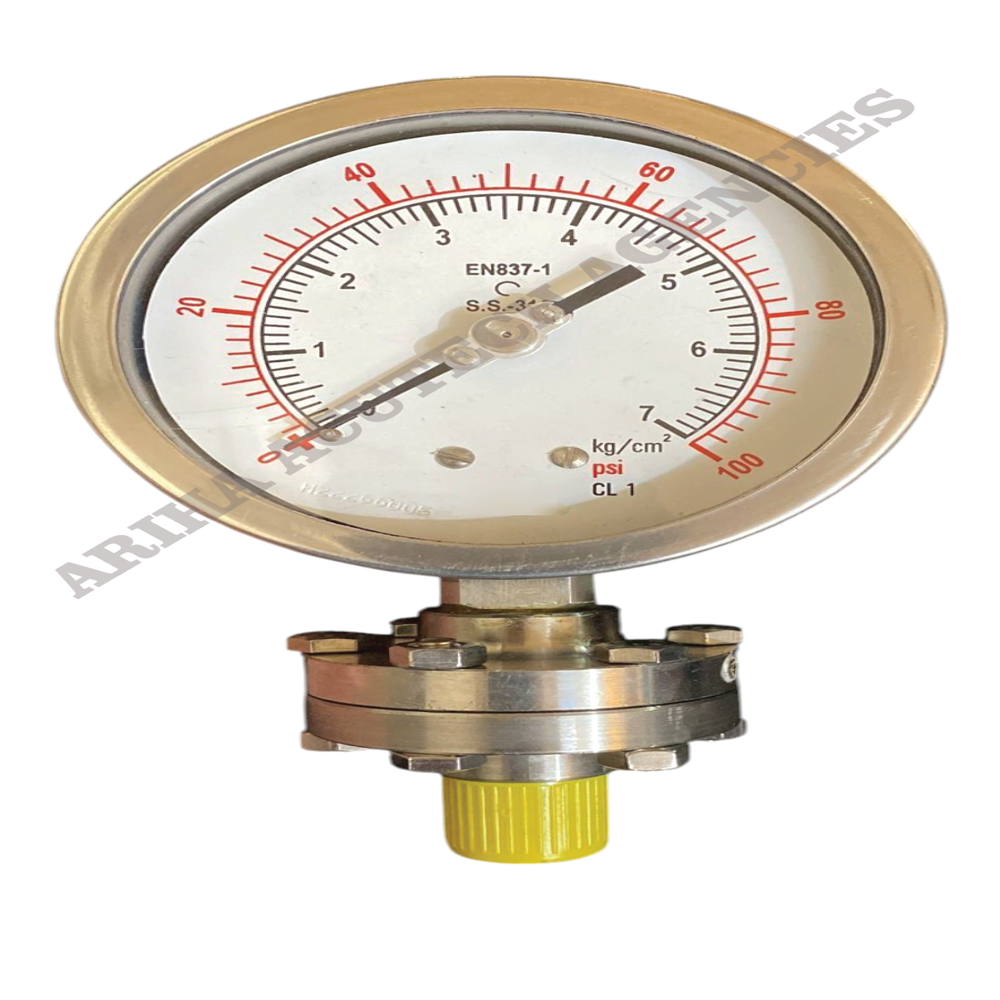

Diaphragm Sealed Gauge

Price 3500.0 INR/ Piece

Diaphragm Sealed Gauge Specification

- Grade

- Industrial

- Display

- Analog

- Material

- Stainless Steel

- Usage

- Industrial

- Dial Material

- Glass

- Pointer Material

- Aluminum

- Processing Type

- Standard

- Product Type

- Diaphragm Sealed Gauge

- Color

- Multicolor

- Mount Type

- Back

- Finishing

- Antique, Matte, Polished, Galvanized

- Measure Pressure Of

- Steam, Oil, Gas, Water

Diaphragm Sealed Gauge Trade Information

- Minimum Order Quantity

- 20 Pieces

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 2000 Pieces Per Month

- Delivery Time

- 8 Days

- Main Domestic Market

- All India

About Diaphragm Sealed Gauge

Price :

Price will be changed according to product details min Price Range Available 1500/pc

Sturdy Construction for Industrial Demands

Crafted from durable stainless steel, the diaphragm sealed gauge offers exceptional resilience against harsh environments like steam, oil, gas, and water. Its glass dial and aluminum pointer ensure long-lasting accuracy and performance, while multiple finish options respond to diverse aesthetic and corrosion resistance needs.

Versatile Measurement and Mounting

With its diaphragm-sealed mechanism, the gauge reliably measures pressure in various applications and environments. The back mount design simplifies installation, making it suitable for numerous industrial settings where secure and visible placement is crucial for safe and efficient operations.

FAQs of Diaphragm Sealed Gauge:

Q: How does a diaphragm sealed gauge improve pressure measurement in industrial settings?

A: The diaphragm sealed design isolates the gauge mechanism from the process fluid, ensuring accurate readings even with corrosive or high-temperature media like steam, oil, gas, or water, commonly encountered in industrial processes.Q: What are the main benefits of using this diaphragm sealed gauge?

A: This gauge provides reliable pressure measurements, resists corrosion due to its stainless steel build, and minimizes maintenance needs. The multicolor analog display and varied finishes also improve readability and longevity, enhancing operational safety and efficiency.Q: When should I choose a back mount diaphragm sealed gauge for my application?

A: You should opt for the back mount version when space constraints or visibility requirements necessitate a rear installation. This mount type is especially useful on control panels and machinery where front mounting isnt feasible.Q: Where can this gauge be used within an industrial facility?

A: It is suitable for installation in areas measuring steam, oil, gas, or water pressure, such as boiler rooms, chemical processing units, pipelines, and manufacturing plants where robust and reliable pressure monitoring is essential.Q: What is the process for installing and maintaining this diaphragm sealed gauge?

A: Installation involves securing the back-mount gauge onto a suitable panel or fixture. Maintenance is simplified by its sealed design, which protects internal components from contamination, reducing manual cleaning and promoting long-term performance.Q: How does the choice of finish impact the gauges longevity and appearance?

A: Available finishesantique, matte, polished, and galvanizedcan be selected based on aesthetic preferences or environmental factors. For example, galvanized and polished finishes offer enhanced corrosion resistance, while matte and antique finishes provide distinctive visual appeal.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Other Pressure Gauge Category

Digital Pressure Gauge

Price 7800.00 INR / Piece

Minimum Order Quantity : 40 Pieces

Product Type : Pressure Gauge

Pointer Material : Aluminum

Dial Material : Glass

Usage : Industrial

Low Pressure Capsule Gauge

Price 1500 INR / Piece

Minimum Order Quantity : 16 Pieces

Product Type : Pressure Gauge

Pointer Material : Aluminum

Dial Material : Glass

Usage : Industrial

Electric Contact Pressure Gauge

Price 800 INR / Piece

Minimum Order Quantity : 50 Pieces

Product Type : Pressure Gauge

Pointer Material : Aluminum

Dial Material : Glass

Usage : Industrial

Commercial Pressure gauge

Price 275.0 INR / Piece

Minimum Order Quantity : 10 Pieces

Product Type : Commercial Pressure gauge

Pointer Material : Brass

Dial Material : Glass

Usage : Industrial

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry